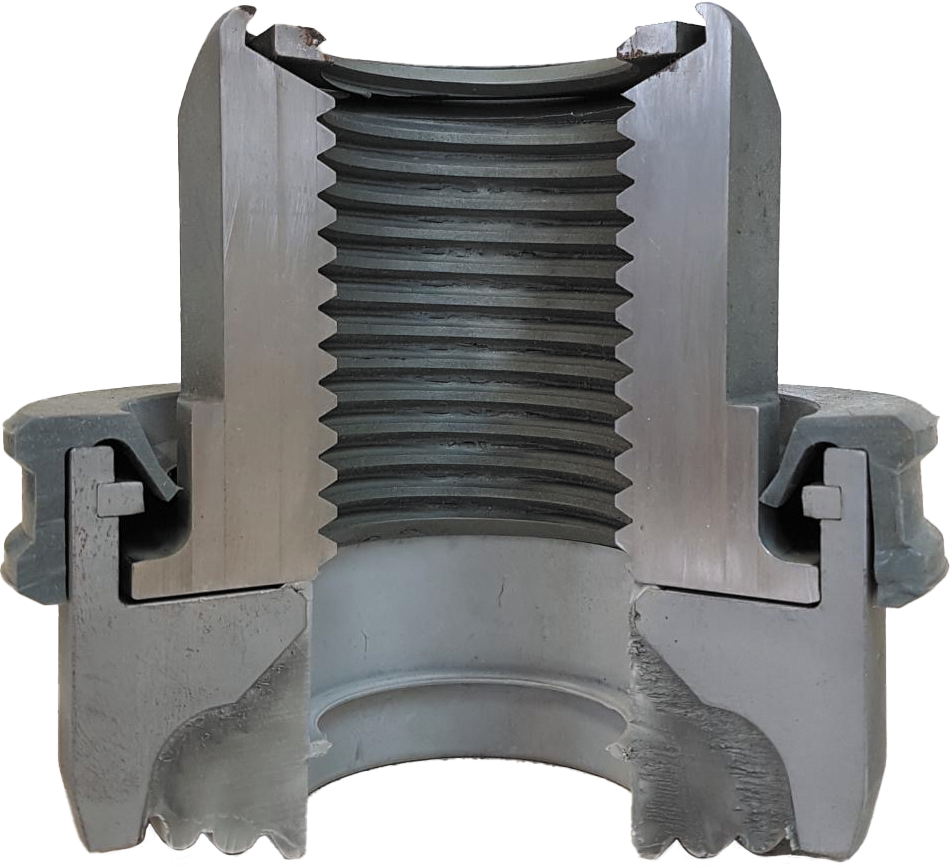

The world’s first and only reusable mill liner fastening system

The Kombo Washer is an interconnected combination washer and nut device used to secure mill liners in mining processing operations globally. Australian designed, owned and patented, the Kombo Washer was developed and proven in the Kalgoorlie Goldfields and is precision manufactured by Flaig & Hommel GmbH in Germany for global distribution.

The patented interconnected design and non-stick elastomer provides for easy handling and significantly faster installation and removal times – maximising mill availability and utilisation by reducing planned and unplanned mill downtime and increasing mill profitability. One gold mining client has proven savings in excess of $500k per reline event using the Kombo Washer.

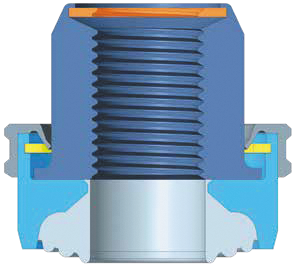

The Kombo Washer is uniquely engineered to completely seal both the bolt hole and thread to prevent slurry fines from migrating up the thread and seizing the nut to the bolt, to take a full clamp load without deforming the sealing elastomer, and to maintain full torque over the reline interval – it holds tight and never loosens during operation, reducing the risk of liner failure.

The Kombo Washer is the world’s first and only reusable mill liner fastening system. Engineered to be reused for 5+ reline events, it provides amortised cost savings and significant sustainability outcomes. Its future proofed design allows for robotic installation and removal.

The Kombo Washer significantly outperforms the legacy 3-piece fastening system that’s been used by the mining industry (unchanged) for more than 100 years. It is available in a full range of metric and imperial sizes.

Our mission

To install the Kombo Washer as the global industry standard for wear plate fastening systems